The content of the article

Natural, warm parquet floors will always be held in high esteem. Over the years, parquet will begin to lose its attractive appearance, but do not rush to change it to modern flooring. If the condition is uncritical - there are no breaks, many broken dies, deep scratches - such a parquet can be easily restored, and at a minimal cost.

First you need to purchase, lend or rent the tools that will be required during the work:

- grinder machine

- looping machine

- sandpaper

- hard putty for wood

- putty knife

- oil or varnish for finishing

Deep parquet restoration

A fairly time-consuming procedure, including the elimination of squeaks, bloating and repair of damaged dies. You need to be completely confident in your abilities, otherwise it is better to entrust this stage to professionals.

Squeak removal

The cause of creaking floors is most often the sagging spacer wedges or the formation of voids under the parquet. In the first case, the plinth is removed and the wedges that have dried up from time to time are replaced by new ones.

If the floors continue to creak for several days, you need to check the plywood under the parquet, which tends to wear out during depreciation. Locally, at the creak, a hole is drilled into which concrete mortar is pumped with a syringe. For two days, the parquet is under pressure, after which the hole is sealed with putty.

Swelling repair

The cause of bloated parquet in most cases is increased humidity. With a small area of damage, the parquet needs to be heated with any powerful hairdryer. As soon as a characteristic parquet smell appears, a load of at least 12-15 kg / dm2 is set in place of the swelling. A clear reduction in swelling suggests that a problem has been found and the procedure should be repeated until it is completely eliminated.

Repair Damaged Dies

Full replacement is subject to dies that have shrunk so much that a gap of more than 5 mm has formed between them and neighboring ones. Such fragments are removed, the remains of the old glue are cleaned and the new die is adjusted to the desired size, after which it is put on the glue in the formed space. In this case, pay attention to the fact that the groove of the new die fits tightly on the spike of the neighboring one. A new die, firmly pressed to the base, is aged for 24 hours under pressure.

Restoring Damaged Dies

If the gaps between the loose dies are small, glue is pumped under them with a syringe and a press is installed for a day.

Surface restoration of parquet

If a deep restoration took place without removing the skirting boards, now this is done first. Then you can proceed with the full restoration of the parquet, thoroughly vacuuming the entire surface before it.

Filling cracks

Small scratches and defects (not more than 1.6 mm) are repaired with putty, which is selected taking into account the tone of the wood. Putty is applied with a spatula to all cracks, it removes excess. After the putty dries, the treated surfaces are cleaned with sandpaper to a perfectly smooth state.

Looping or grinding

Both processing methods involve the complete cleansing of floors from old varnish.

Floor cycling. It is advisable to carry out galvanizing with a parquet thickness of at least 1.5 cm. A looping machine removes a layer of wood up to 3 mm, but returns the original color and beauty to the floors. Flooring in this way should be clearly along the fibers.Mechanical cycling of floors is carried out using a looping machine, it is an easy, relatively clean and highest quality way to bring the floors in proper form.

Manual scrolling takes place with the help of a special tool - manual cycles. The method is cheap, but laborious, requiring patience and certain skills, otherwise the result may be a rough and uneven surface. With this method, the parquet is wetted with water or steamed with an iron through a wet cloth.

Grinding floors. Using a grinder, floor cycling can be completely replaced while saving a couple mm of wood. The grinder carefully removes the old varnish, and the surface grinder gives the parquet perfect smoothness. In hard-to-reach places a circular grinder should be used. A clear advantage of grinding can be called the fact that grinding is performed both along and across the fibers, in contrast to looping.

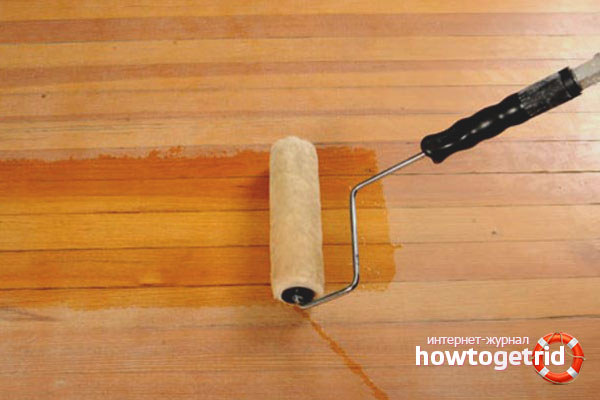

The final stage: varnish or oil

After grinding is completed, the floors should be thoroughly vacuumed. Then decide whether the previous color scheme remains, or modify it with a stain, which, depending on the chosen color, can enhance or change the original shade of the tree.

It is possible to cover the restored parquet with oil even if it was originally varnished. Oil has the ability to penetrate into the deeper layers of the tree, so the first layer should be applied to the surface of the oil with a high solvent content. For the final layer, thicker oil compositions are used. After half an hour, the remnants of the non-absorbed oil are removed with a clean rag and you can walk on the parquet the next day.

It is better to apply varnish in several thin layers. Only with decent experience will it be possible to make this procedure an even layer of the same thickness. Natural varnishes dry for several days, and polymer varnishes - for several hours. It is not so difficult to give new life to old parquet floors, besides, labor costs and tool rental more than compensate for the saved money, because the work of professionals is not cheap.

Parquet Care

In order to keep the parquet floor like new for a long time, basic care rules should not be neglected: regularly moisten with a well-wrung soft material and periodically polish with professional means to protect parquet floors. Then the parquet will serve for many more years, giving your beloved house warmth and coziness.

Video: do-it-yourself parquet repair

Submit